IMPORTANT CONSIDERATIONS IN HEAT EXCHANGER SELECTION

As the name of the heat exchanger implies, this device has a duty of heat exchange between two fluids. the fluids can be water, gas, oil, air, etc.

Types of heat exchangers in central heating and air conditioning system according to building type are as follows :

- Plate heat exchanger

- Shell & tube heat exchangers

- Fin Heat Exchanger ( air-cooled heat exchangers)

EACH OF THE MENTIONED TYPES IS DIVIDED INTO THE FOLLOWING SUBGROUPS:

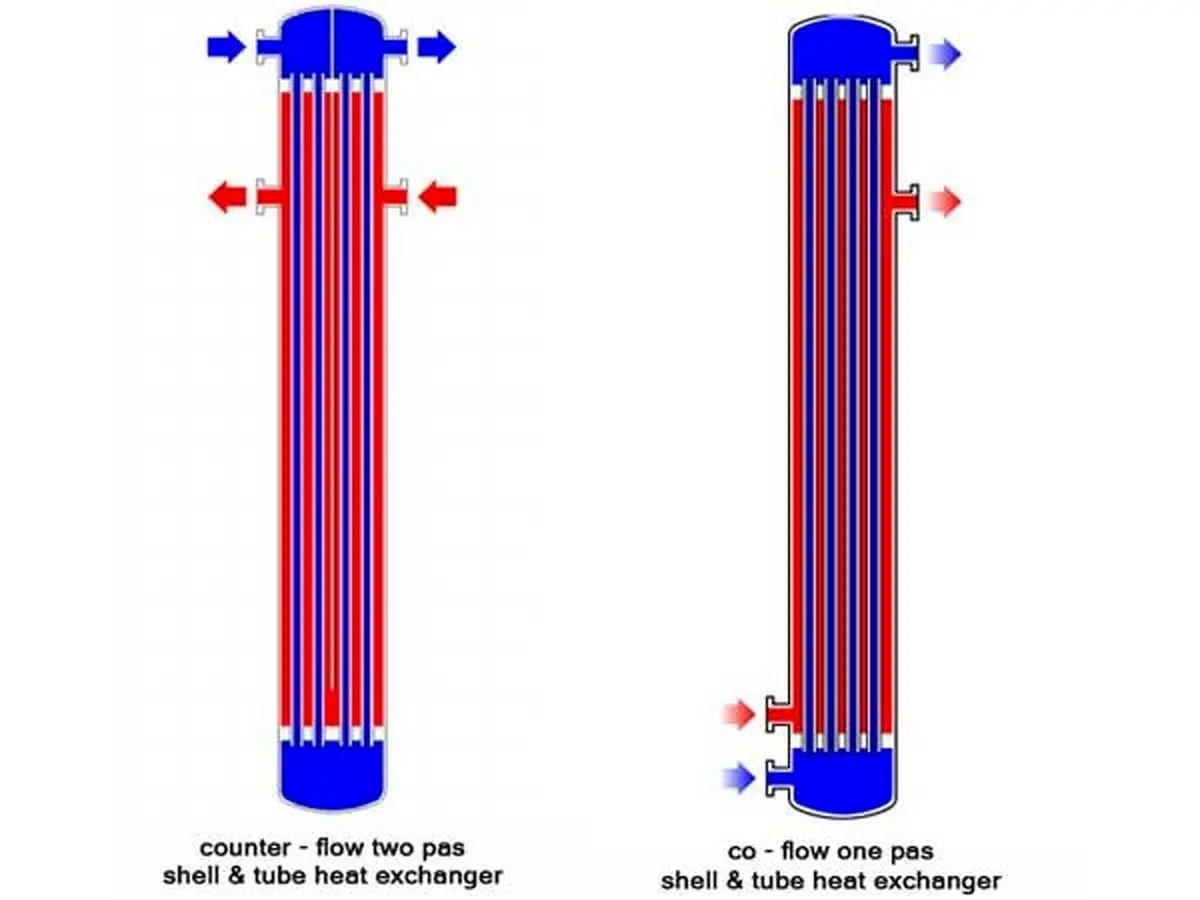

- Co-flow Heat exchangers

- Crossflow Heat exchangers

- Counterflow Heat exchangers

SHELL AND TUBE HEAT EXCHANGERS

Shell and tube heat exchangers are very popular in air conditioning, pools, and even chemical industries. As indicated by their name, they include a high-pressure, large cylindrical tank (shell) housing a number of tubes. The liquid moves through the pipes and hot water or steam passes over these tubes inside the shell. A large number of the said tubes and their great contact surface effectively transfer heat to the liquid in the tube and heat it up.

Shell and tube is the most popular type of heat exchangers which are categorized into different sub-types based on the number of tube and shell passes. The simplest kind features a single pass of tube and shell (figure below). These heat exchangers usually have a partition inside, also known as baffles, which creates turbulence and lateral-velocity in the flow and therefore increases the convective coefficient of the fluid in the shell. Heat exchangers with baffles usually have a single pass of shell and two passes of tubes or two passes of shells and four passes of tubes. The fluid is directed perpendicular to the tubes between the two adjacent baffles.

U-shaped shell and tube heat exchangers are the cheapest of their kind as they only require a single tube plate. The tube interior cannot be cleaned mechanically due to the sharp U-turn. These exchangers use an even number of tube passes and are not limited in terms of thermal expansion.

A. In shell and tube heat exchangers, the tubes are responsible for heat exchange, such that the two sides of a tube are in contact with fluids at different temperatures. They act as a separating element and come in different sizes. They are mostly made of copper, however, can also be manufactured from stainless steel, nickel, aluminum, brass, or titanium. Considering the heat transfer coefficients of the fluids inside and outside of the tube, fins, and baffled tubes can be employed on the side with a lower coefficient, which also imposes some costs.

B. The shell and the tube sheets hold the tubes and connect the inlets and outlets. Tube thickness depends on the operating pressure and shell thickness.

The shell is normally made of stainless steel as it needs to offer the lowest level of heat transfer while providing high-pressure tolerance. The shell will hold the water inlet and outlet, the hanging hook, discharge valve, sensor safety valve, and other components.

Different flow regimes can exist on the shell and tube sides in these exchangers. The regime types are selected according to attributes such as heat transfer surface, operating pressure, coil pressure drop, manufacturing process, corrosion-control costs, and maintenance. Baffles are used to increase the heat transfer coefficient at the shell side and to better secure the tubes.

ADVANTAGES OF HEAT EXCHANGERS

- Wide application

- Ease of maintenance

- High heat transfer surface to volume ratio

PLATE HEAT EXCHANGERS

- Plate heat exchangers have been in use for more than 100 years, and come in gasket and brazed variants. The gasket types are mostly used in air conditioning, food industries, petrochemical industries, painting section of automobile production, petroleum industries, etc. They also include frame costs compared to brazed heat exchangers and therefore are more expensive at identical sizes and capacities. However, they offer easy scalability, repair, and maintenance compared to the gasket types.

- Due to the significantly high total heat transfer coefficient, small dimensions, and higher efficiency of plate heat exchanger compared to conventional shell and tube heat exchanger (such as coil and double-glazed resources), they have the ability to instantly supply hot water consumption for the consumer without any need for storage (such as coil and double-glazed resources) and completely hygienic, especially when the softener is installed on the path of the inlet cold water.

- Welding heat exchangers are mainly used for supplying the hot water consumption in buildings, water heating of pools, floor heating systems, oil cooling, and an evaporator and condenser in chillers. They should be calculated accurately in all cases except for hot water consumption. In this regard, you can negotiate with the experts of the DamaTajhiz engineering company.

Gasketed plate heat exchanger

Welded plate heat exchanger

AIR-COOLED OR FINNED HEAT EXCHANGERS:

- Finned heat exchangers are mainly used for “gas- gas” or “liquid- gas” applications that

are widely used in various industries including refrigeration in very low temperature such as condenser and evaporator in fridge system, energy recovery, process industries, refrigeration, and air conditioning systems such as cold water coil, warm water for HAU, fan coils, warm water coil of heater units…. Fanned plate heat exchangers are used in gas turbines, nuclear power stations and propulsion engineering, refrigeration, heating and air conditioning of excess heat recovery systems, and chemical industries and cooling.

- Since water flow in all heat exchanger processes results in scale formation (calcium, magnesium, and zinc minerals) on heat exchanger surfaces of various types of heat exchangers (shell& tube and plate) and this leads to great loss in heat exchange efficiency, it is necessary to install softener or descaler in the path of input water in order to preserve their efficiency.

- In a time of selecting heat exchanger required for the project, in addition to calculation and determination of capacity and heat transfer area, type, size and also the material of heat exchanger, important factor of water pressure loss in coil or heat exchanger plates (and air passing through heat transfer coils) should be determined for calculation of circulator pump´s head or static pressure of aeration fan.

The heat exchangers are also used in the swimming pools, sauna, and jacuzzi heating systems. In the picture seen below, the location of the heat exchangers, as the heating system of the pool, along with other pool equipment is precisely determined.

Due to its steel body, Plate heat exchangers are simply used to heat the pool water. However, it should be noted that the heat exchanger should be placed after the filter and before disinfecting equipment such as chlorinator.

For Heat Exchangers, www.damatajhiz.com is the reference, most-visited website in the Middle East (since 2004, source: Alexa.com rankings). With a little patience, you can find brief, sufficient information about your desired product and purchase it at the best price (guaranteed best deal) with excellent after-sales services and a reliable guarantee.

COMPARISON OF THE PLATE HEAT EXCHANGER WITH SHELL AND TUBE HEAT EXCHANGER

|

|

Plate heat exchanger |

shell and tube heat exchanger |

|

Temperature intersection |

Not possible |

possible |

|

Operating temperature difference |

About 1 centigrade |

About 5 centigrade |

|

Multitasking |

possible |

Not possible |

|

Pipe fittings |

one direction |

multi directions |

|

Heat transfer coefficient |

3-5 |

1 |

|

Operating Weight ratio |

1 |

3-10 |

|

Storage volume |

low |

high |

|

Space coefficient |

1 |

2-5 |

|

boiling |

No |

Yes |

|

Vibration sensitivity |

Not sensitive |

sensitive |

|

gasket |

On each plate |

On each lid |

|

leakage detection |

easy |

hard |

|

Access for inspection |

No limit on each side |

limited |

|

Disassembling time |

Up to 15min |

From 60 to 90 min |

|

Repair |

Replacing plates or gaskets |

Changing or blocking tubes |

|

Heat value correction |

Easily by adding or removing plates |

complicated |

|

Sediment Coefficient |

0.1-0.25 |

1 |

Important to determine the pressure drop of water flowing through the coils or heat exchanger plates (and air passing through the heat transfer coils) in order to calculate the head of the pump circulator or the static pressure of the aeration fan.

Also correct calculation of inlet and outlet water pipe diameter of heat exchangers with water as working fluid leads to the deliverance of sufficient fluid enabling needed heat transfer in the heat exchanger.

The following diagram can be used to calculate the diameter of steel tubes in heating and cooling systems.

INSTALLATION TIPS FOR INSTALLING PLATE HEAT EXCHANGERS:

- The plate heat exchanger can be installed horizontally and vertically, but in both situations, it should be noted that the converter has to be installed in such a way that air can easily flow out.

- In a horizontal position, it is best to place the head of inlet and outlet pipes upward and in the vertical position, the heads of these pipes should have a little slope upward.

- It is recommended to use a chassis for the installation of a large plate heat exchanger so that it is fixed without excess weight being applied to the tubes or to avoid placing it directly on the floor of the engine room. The most important point in installing a plate converter is how the input and output pipes are connected.C

DamaTajhiz Site: https://damatajhiz.com/en/